Hitachi Launches Hitachi Digital Solution for Logistics/Delivery Optimization Service

Contributing to logistics cost reduction and higher operational efficiency

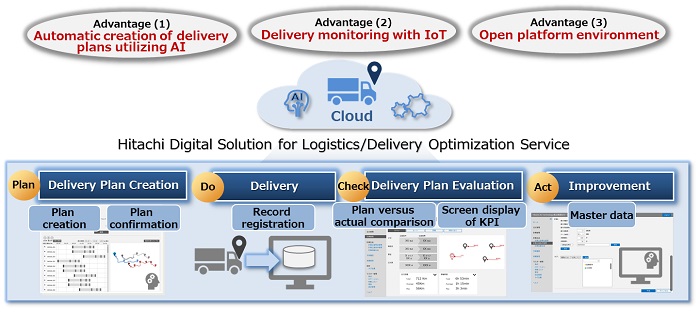

Hitachi, Ltd. announced that it will release “Hitachi Digital Solution for Logistics/Delivery Optimization Service” on April 1, 2019, that creates effective delivery plans by utilizing advanced digital technology such as AI and IoT for logistics operations in Japan, the People’s Republic of China and the Kingdom of Thailand. By analyzing data with Hitachi’s original algorithm utilizing AI, the Service quickly and automatically creates delivery plans, such as allocating destinations and delivery timing to each vehicle, and determining delivery routes, which are conventionally done by expert workers taking various requirements into consideration and are very time consuming. In addition, the Service compares and visualizes delivery plans and results by utilizing GPS data of trucks’ actual delivery record. As the result of a PoC(Proof of Concept) with a customer, utilizing the Service to support logistics cost reduction and more efficient logistics operations, Hitachi has confirmed up to a 10% reduction in the number of delivery trucks compared with the conventional method.

Including the Service, Hitachi will systemize and provide services as “Hitachi Digital Solution for Logistics”, that help optimize value chains by gathering, stocking and analyzing customer data in logistics operations. Moving forward, Hitachi will promote the expansion and enhancement of the service lineup to support logistics cost reduction and higher operational efficiency, and contribute to digital innovation in the logistics field.

Recommended AI News: JFrog Drives DevOps Fast-Forward, Unveils New Software Distribution Capabilities

Recently, in the logistics industry, due to the popularity of e-commerce and the diversity of delivery needs, the driver shortage and long working hours have become a large issue. In China and Thailand, the needs of Milk run (1) and joint delivery are also increasing in industries, including manufacturing, making efficient delivery plans vital. Currently, delivery planning is dependent on the knowledge of expert workers, and further efficiency and operational workload reduction are becoming challenging.

Under these circumstances, through collaborative creation and PoC with customers in Japan, China and Thailand, Hitachi has advanced development and improvement of the Service as a Lumada Industry Solution for digital innovation in the logistics field. As a result of the PoC with Mitsui & Co., Ltd., Hitachi has confirmed the effects that it can reduce the number of trucks up to 10% (2) compared with the conventional method, and quickly (3) create delivery plans equivalent to or more effective than expert workers. The Service includes the following advantages.

Recommended AI News: Applitools Visual AI Reaches One Billion Images Analyzed

1. Automatic creation of effective delivery plans with Hitachi’s original algorithm incorporating expert workers’ knowledge

By making all important conditions for the delivery planning (delivery time, location of logistics center/base, delivery routes, traveling time, traffic jams, time to load and wait at the store, vehicle rank (4), driver conditions and other factors) into variables (5), and with data analysis using Hitachi’s original algorithm that incorporates expert workers’ knowledge (order decision for use of truck parking spaces, arranging multiple delivery date candidates and other factors), the Service enables the automatic creation of efficient delivery plans (allocation of destination and time per vehicle, delivery routes, loading rate, working hours, travel distance and other factors). In addition to utilizing AI, by reflecting expert workers’ knowledge on the logic of planning, customers can quickly create plans without depending on the know-how of expert workers.

2. Improved delivery accuracy by comparing/visualizing delivery plans and results and by analyzing data

By acquiring truck travel records with GPS and coordinating data, the Service can automatically create delivery results. This enables the comparison and visualization of delivery plans and results (delivery time, routes, tasks per vehicle and driver, delivery costs, delivery delay rate, and other factors) on the screen of the Service. Hitachi can assist customers to improve the precision of delivery plans by analyzing this data and reflecting it in configurations concerning plan creations. However, in the future, Hitachi plans to add an analysis function utilizing AI in order for customers to improve it by themselves.

3. Open environment that allows for connecting various data

Hitachi’s open Lumada Platform Services enable coordination with system data that customers are already using, third party services and open data. Hitachi quickly and flexibly provides an environment suitable for customer needs.

- A method of procurement and logistics by having a logistics operator traveling around multiple parts suppliers to collect parts and others.

- A result of comparison and verification between result data of three companies (four centers of logistics warehouses) for six months and the results of simulation using the Service.

- The Service automatically creates a monthly delivery plan in one or two hours, which is conventionally created in one or two days by multiple expert workers.

- Types of trucks (vehicles) (for example, a two-ton car, a four-ton car)Making it to values used for constraints and priorities.

Recommended AI News: Vonage Enables Omnichannel Customer Experience For Koopid