Prusa Research Shows The Future Of Manufacturing At The EXPO 2020 Dubai

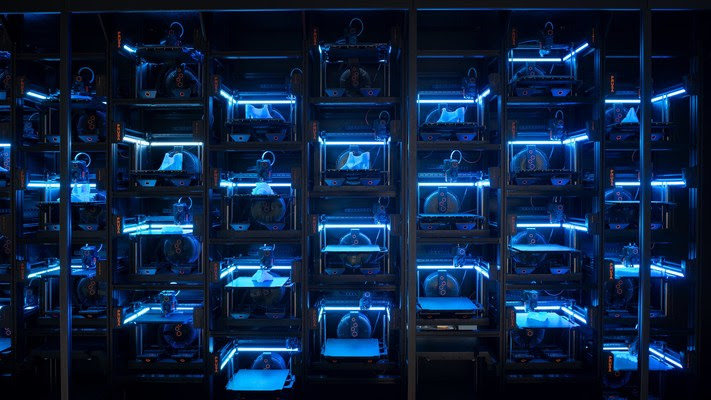

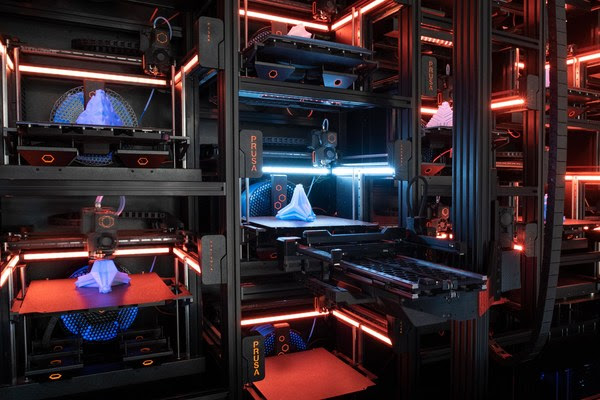

Prusa Research, the producer of the acclaimed Original Prusa 3D printers, has prepared an interactive exhibition for the EXPO 2020 Dubai. The sample of Prusa Pro AFS (Automated Farm System) consists of 34 Original Prusa 3D printers, working completely without human operators.

The automated printing farm has been introduced at the EXPO 2020 Dubai, as a part of the exhibit “The Future of Manufacturing by Prusa 3D.” Using touchscreen tablets, the visitors can select and generate unique snowflake designs, which are then printed from fluorescent plastic. The printed snowflakes can be added to a dynamically growing sculpture that is part of the exhibit.

Recommended AI News: A-LIGN Delivers Industry’s Most Comprehensive Ransomware Preparedness Assessment Service

The endless variations of snowflakes demonstrate the advantages of 3D printing: no matter how complex and unique the model is, production can start immediately. There are no costs and complications, for example, with mold manufacturing. The printing farm makes local manufacturing easily possible for customized outputs and products. Compared to machine milling, there is less waste and the printing material (filament), and there are plans for using recycled material in the near future.

This is a leap forward both on the hardware and software levels. The printers are different from the regular production models. Their design and construction allow for placement into a special scalable rig, featuring mechanisms responsible for automatic collection and dispensing of the finished 3D prints. In-house developed software takes care of the whole farm, with smart algorithms for assigning print tasks, monitoring all ongoing processes, and collecting data. All the user has to do is select a print using the touchscreen tablet and then wait for the finished print to be dispensed.

Recommended AI News: Talon Launches First Corporate Secure Browser for the Hybrid Work Era Backed by Renowned Cyber Security Industry Leaders

Prusa Research develops and manufactures 3D printers directly in their headquarters in Prague, Czech Republic. The company runs their own printing farm there, with 600 printers running simultaneously, manufacturing parts for new 3D printers. The main advantage of this method is that new or updated part designs can be put immediately into production with no extra steps or delays. While this farm is still controlled by operators working shifts, the new model introduced at EXPO 2020 Dubai is fully automated and requires very little maintenance.

“We run the biggest 3D printing farm in the world, so we have the experience to design the ideal workflow. Our priority was to make the operation as easy as possible,” says Josef Prusa, CEO of Prusa Research. “The farm we are introducing in Dubai is going to be available commercially. We already have customers that run dozens of our 3D printers at once, either for prototyping or small-series manufacturing. We want to offer them this automated printing farm with uncomplicated operation and maintenance.”

Prusa Research is a leading 3D printer manufacturer based in Prague, Czech Republic. The company was founded as a one-man start-up in 2012 by Josef Prusa, a Czech hobbyist, maker and inventor. It all started as a hobby when Prusa began to explore the possibilities of open-source 3D printers, gradually improving and expanding them—making them accessible to mainstream users. Just a couple of years were enough to turn a small garage project into a globally recognized brand with more than 600 people on board. Today, several large development teams within the company are focused on pushing 3D printing technologies even further with new 3D printers, advanced software and better printing materials.

Recommended AI News: Palo Alto Networks Partners with Ingram Micro to Bring Okyo Garde to Small Businesses

[To share your insights with us, please write to sghosh@martechseries.com]

Comments are closed.